Smooth start Voltage 20V (DC) Battery capacity 2.0Ah Motor type Brush motor Oscillations 8,000 - 19,000 OPM Oscillations angle 3.2 degree Charger 21V 0.5...

See Details-

Electric Woodworking Saw

-

Multifunctional oscillating Saw

-

Power Drill

-

Rotary Hammer Drill

-

Impact Wrench

-

Electric Screwdriver

-

Angle Grinder

-

Handheld Pressure Washer

-

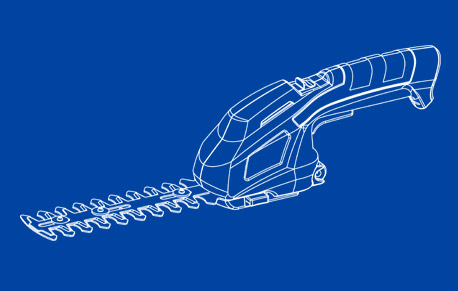

Handheld Lawn Mower

-

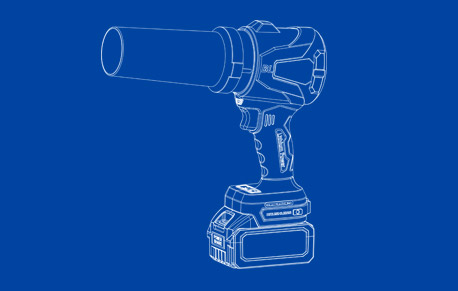

Lithium Turbo Jet Blower

-

Electric Pruning Shears

-

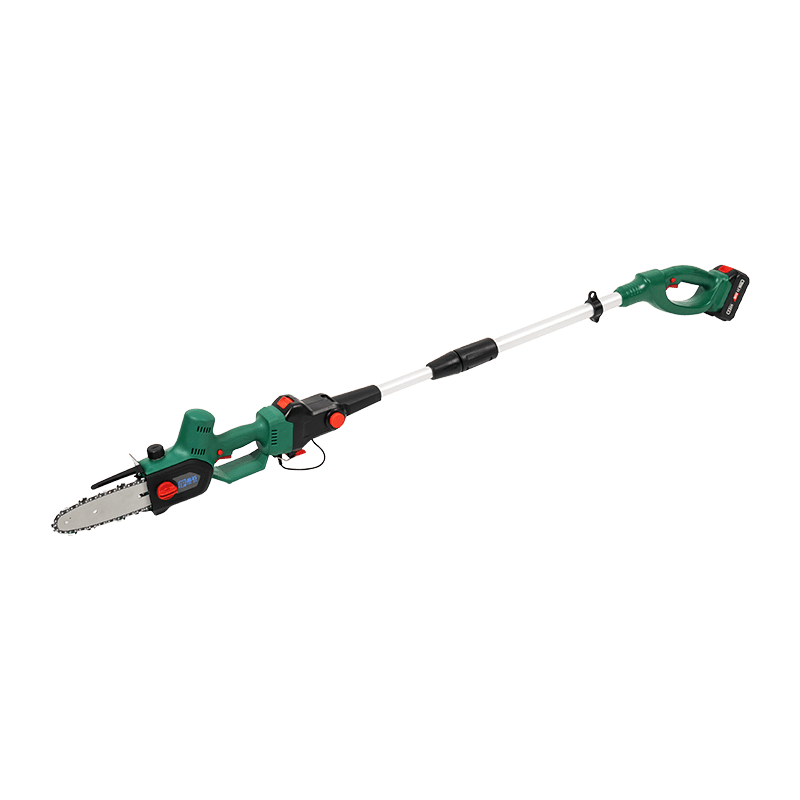

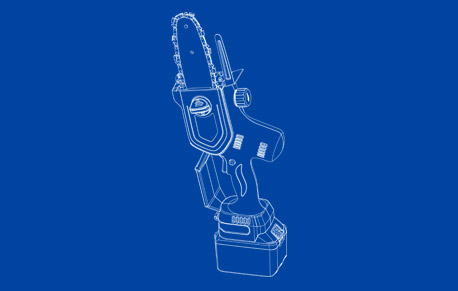

Lithium ChainSaw

-

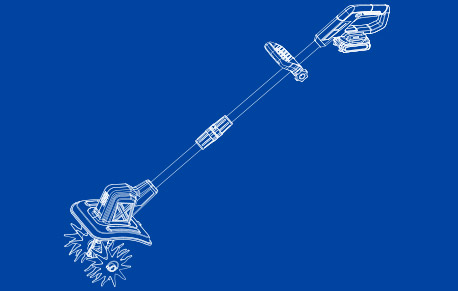

Handheld Tiller Cultivator

-

Plant Watering Devices

-

Air Pump

Electric Screwdriver: What the Industry Is Actually Debating Right Now

What Exactly Is an Electric Screwdriver Today?

The shifting meaning of "electric screwdriver" in modern tool ecosystems

The term "electric screwdriver" was once easy to explain. It referred to a compact, corded or battery-powered tool designed primarily for driving screws at relatively low torque and speed. Its role was narrow, its structure simple, and its user base clear. Today, that clarity no longer exists. As motor technology, battery systems, and electronic controls have evolved, the electric screwdriver has absorbed features once exclusive to drills, impact drivers, and other multifunction power tools. At the same time, lightweight assembly tools have adopted characteristics traditionally associated with industrial fastening equipment. The result is a category whose boundaries are increasingly difficult to define.

In many markets, the phrase "electric screwdriver" now describes a spectrum rather than a single product type. At one end are pen-style tools for electronics assembly, and at the other are compact brushless drivers capable of handling construction-grade fasteners. This expansion has made the term more flexible, but also more ambiguous.

The blurred boundary between traditional screwdrivers and brushless power tools

One of the most important forces reshaping the definition of the electric screwdriver is the widespread adoption of brushless motors. Traditionally, electric screwdrivers used brushed DC motors, which limited torque output, duty cycle, and lifespan. Brushless motors have changed these constraints by allowing higher efficiency, better heat management, and electronic control of speed and torque. As a result, tools marketed as electric screwdrivers can now deliver performance levels that overlap with compact drills and light-duty impact drivers.

This technological overlap raises practical questions. When a tool has a brushless motor, variable speed trigger, electronic torque control, and interchangeable bits, does it remain an electric screwdriver, or does it become a reduced-size power drill? Different manufacturers answer this question differently, often based on marketing strategy rather than functional distinctions. The name may stay the same, but the user experience and application range have expanded well beyond the traditional definition.

Lightweight handheld assembly tools versus multifunction electric tools

Another area of tension lies between lightweight assembly-focused screwdrivers and multifunction electric tools. Assembly tools emphasize control, repeatability, and ergonomics. They are often designed for prolonged use, precise torque settings, and compatibility with fixtures or balancers. Multifunction electric tools, by contrast, emphasize versatility. They may support drilling, screwdriving, and even light fastening tasks across different materials.

The conflict arises when a single tool attempts to serve both purposes. Many modern electric screwdrivers are marketed as suitable for furniture assembly, appliance installation, and light construction work. While this versatility appeals to consumers, it can dilute the expectations of professional users who prioritize consistency and precision over flexibility. As a result, the same product may be viewed as an assembly tool in one context and a general-purpose power tool in another.

Inconsistent classification across consumer, semi-professional, and production-line tools

Unlike categories such as "cordless drill" or "impact wrench," the classification of electric screwdrivers lacks unified standards. Consumer-grade products are often defined by price, battery capacity, and ease of use. Semi-professional tools may add higher torque, improved durability, and brushless motors, yet still be labeled as electric screwdrivers. Production-line tools, meanwhile, are classified based on torque accuracy, repeatability, and integration with quality control systems rather than by name.

This inconsistency makes it difficult to draw clear lines between user segments. A tool described as an electric screwdriver in a retail setting may be unsuitable for continuous industrial use, even if its specifications appear similar. Conversely, an industrial screwdriver may not resemble what consumers expect when they hear the same term.

| Category | Typical Torque Range | Primary Focus | Common Users |

|---|---|---|---|

| Consumer Electric Screwdriver | 1–6 Nm | Ease of use, compact size | Home users, DIY |

| Semi-professional Electric Screwdriver | 5–20 Nm | Versatility, higher power | Installers, service technicians |

| Industrial Assembly Screwdriver | 0.3–30 Nm (controlled) | Precision, repeatability | Production lines, OEM factories |

Market-specific interpretations of the term "electric screwdriver"

Geographic and cultural factors further complicate the definition. In some European markets, "electric screwdriver" is closely associated with assembly-line tools and precision fastening. In North America, the same term is often used interchangeably with compact cordless drivers aimed at home improvement. In parts of Asia, electric screwdrivers are strongly linked to electronics manufacturing and light industrial assembly.

These regional interpretations influence not only product design but also naming conventions and pricing. A tool positioned as an electric screwdriver in one market may be marketed as a cordless driver or light drill in another, even if the hardware remains unchanged. This divergence affects customer expectations and makes global product positioning more complex.

The role of torque control and fastening accuracy

Torque control has become a defining factor in how electric screwdrivers are differentiated from other power tools. Traditional screwdrivers relied on mechanical clutches with limited accuracy. Modern designs increasingly use electronic torque control, current sensing, or shut-off mechanisms to improve consistency. In industrial contexts, torque accuracy and traceability are often more important than maximum power.

This focus on control reinforces the identity of the electric screwdriver as a fastening-specific tool, even as power and speed increase. However, when consumer-grade tools advertise torque settings without clear accuracy standards, the distinction becomes less meaningful. The same feature can signal precision in one context and convenience in another.

Battery systems and their impact on tool identity

Battery technology has also reshaped expectations. Early electric screwdrivers used small, low-voltage batteries with limited runtime. Today, lithium-ion platforms offer higher energy density and compatibility across tool families. Some electric screwdrivers share batteries with drills, saws, and grinders, reinforcing their inclusion in broader power tool ecosystems.

At the same time, ultra-compact tools with built-in batteries continue to exist, particularly for electronics and light assembly. These two approaches represent different philosophies. One treats the electric screwdriver as a specialized tool optimized for a single task, while the other treats it as a modular component of a multifunction system.

Pricing strategies shaped by definition ambiguity

The lack of a unified definition directly affects pricing. Consumers may compare an electric screwdriver priced at a low entry point with a higher-priced brushless model and question the difference, even though the intended use cases diverge. In industrial procurement, buyers may focus on specifications such as torque repeatability and service life, accepting higher prices without associating them with consumer benchmarks.

This pricing spread can be confusing when the same term is applied across all segments. Without clear contextual framing, the value proposition of an electric screwdriver becomes harder to communicate, especially in cross-border or online sales channels.

Electric screwdriver as a function rather than a fixed product category

Given these overlaps and inconsistencies, it may be more accurate to view the electric screwdriver as a function rather than a fixed product category. The core function is controlled screwdriving, but the form, power level, and feature set vary widely. Some tools prioritize speed, others prioritize control, and others balance both.

This functional perspective helps explain why the boundaries continue to blur. As long as fastening remains the primary task, manufacturers can justify using the term "electric screwdriver," even when the tool’s capabilities approach those of more general-purpose power tools. The definition, therefore, is shaped less by strict technical limits and more by intended application, user expectation, and market context.

Why Is the Electric Screwdriver Category Drawing Renewed Attention?

The return of home DIY and the rising demand for lightweight tools

In recent years, home DIY has regained momentum across many regions. Changes in lifestyle, extended time spent at home, and increased interest in self-sufficiency have all contributed to a renewed willingness among consumers to assemble, repair, and modify household items on their own. Within this context, lightweight electric screwdrivers have become particularly appealing. They lower the physical and psychological barriers to entry for users who may find traditional power tools bulky, noisy, or intimidating.

Unlike drills or impact drivers, electric screwdrivers are often perceived as approachable. Their compact size, reduced weight, and simplified operation align well with casual or occasional use. As furniture increasingly arrives in flat-pack form and home improvement projects shift toward modular and user-assembled products, the need for a tool that balances convenience and control has grown. This shift has placed the electric screwdriver back into focus as a practical household tool rather than a niche accessory.

Lightweight design as a response to changing user expectations

Modern users often prioritize ease of handling over raw power. For many DIY tasks, excessive torque is unnecessary and even undesirable. Lightweight electric screwdrivers respond to this preference by offering sufficient fastening capability without the fatigue associated with heavier tools. This design philosophy reflects a broader trend in consumer products toward usability and comfort.

Manufacturers have responded by refining ergonomics, improving grip design, and reducing overall form factor. These adjustments make electric screwdrivers suitable for a wider demographic, including users with limited hand strength or those performing tasks in confined spaces. The renewed attention to this category is therefore tied not only to what tasks people perform, but also to how they expect tools to fit into their daily routines.

Growth in electronics assembly and appliance repair scenarios

Beyond household DIY, demand is also increasing in more specialized scenarios such as electronics assembly, device refurbishment, and small appliance repair. As consumer electronics become more modular and repair-friendly in some markets, technicians and hobbyists alike require tools that provide controlled fastening without damaging delicate components.

Electric screwdrivers are well suited to these environments. Their lower torque ranges, finer speed control, and compatibility with precision bits make them preferable to heavier power tools. In repair workshops, service centers, and even educational settings, the electric screwdriver occupies a space between manual tools and industrial fastening equipment. This expansion of use cases has contributed to renewed interest from both users and manufacturers.

The influence of right-to-repair and sustainability discussions

Discussions around sustainability and right-to-repair have also played a role in reshaping tool demand. As consumers become more conscious of product lifecycles, there is growing interest in repairing rather than replacing devices. Electric screwdrivers support this behavior by enabling controlled disassembly and reassembly of products ranging from smartphones to household appliances.

This trend has elevated the electric screwdriver from a convenience item to a practical enabler of repair culture. In this context, attention is not driven by novelty, but by relevance. Tools that support maintenance and longevity naturally gain renewed interest when broader social and regulatory conversations encourage these practices.

Industrial assembly knowledge moving into the consumer market

Another factor drawing attention to the electric screwdriver category is the transfer of industrial assembly experience into consumer-oriented products. For decades, industrial screwdrivers have been designed around repeatability, torque control, and operator comfort. Manufacturers with experience in these environments are increasingly applying similar principles to tools aimed at home users and small workshops.

This downward transfer does not mean industrial specifications are simply copied. Instead, concepts such as electronic torque limitation, soft-start functions, and improved balance are adapted to meet consumer expectations. The result is a new generation of electric screwdrivers that feel more refined and predictable than earlier models, reinforcing the category’s relevance.

| Feature Origin | Industrial Context | Adaptation in Consumer Tools |

| Torque control | Assembly consistency | Damage prevention for DIY tasks |

| Ergonomic balance | Reduced operator fatigue | Comfort for prolonged home use |

| Electronic shut-off | Process reliability | Simplified user experience |

Battery technology enabling new form factors

Advances in battery technology have made it possible to rethink the form and function of electric screwdrivers. Lithium-ion cells offer higher energy density and more stable output than earlier battery types. This allows tools to be smaller without sacrificing runtime, or to deliver more consistent performance over a discharge cycle.

As a result, manufacturers can design electric screwdrivers that are slim, pen-shaped, or integrated into unconventional housings. These designs appeal to users who value portability and storage efficiency. Battery improvements also reduce charging times and extend service life, addressing common frustrations associated with earlier generations of electric screwdrivers.

Motor advancements reshaping performance expectations

Motor technology has evolved alongside batteries. The introduction of compact brushless motors into smaller tools has expanded what electric screwdrivers are capable of delivering. Higher efficiency and better speed control allow these tools to operate smoothly across a wider range of tasks.

This does not necessarily push electric screwdrivers into the territory of heavy-duty tools. Instead, it allows them to maintain controlled output while improving responsiveness and durability. Users begin to expect quieter operation, smoother startup, and more predictable behavior, all of which contribute to renewed attention toward a category once seen as basic.

The redefinition of value in a mature category

Electric screwdrivers are not a new invention, yet their perceived value is being reassessed. In the past, they were often treated as entry-level tools or promotional items. Today, improved materials, electronics, and design have repositioned them as purposeful solutions for specific needs.

This shift encourages consumers to compare features more carefully rather than viewing all electric screwdrivers as interchangeable. Manufacturers, in turn, invest more effort into differentiation, which further increases visibility and discussion around the category.

Market segmentation becoming more nuanced

The renewed attention also reflects more nuanced market segmentation. Instead of a single broad category, electric screwdrivers are now positioned for distinct user groups, including casual DIY users, repair enthusiasts, service technicians, and light assembly operators. Each segment values different attributes, from simplicity to control to compatibility with accessories.

This segmentation allows the category to grow without relying on a single definition of success. It also explains why electric screwdrivers continue to attract attention despite competition from multifunction power tools. Their relevance is sustained by adaptability rather than by competing directly on power.

A category reshaped by context rather than replacement

Ultimately, the renewed attention surrounding electric screwdrivers is not driven by the replacement of other tools, but by changing contexts of use. As tasks evolve and user expectations shift, tools that align closely with these changes naturally regain focus. The electric screwdriver, supported by advances in batteries, motors, and design thinking, fits into this evolving landscape in a way that feels timely rather than outdated.

When Do Users Actually Choose an Electric Screwdriver Instead of a Drill?

Precision assembly scenarios where control matters more than power

Users tend to choose an electric screwdriver over a drill when the task involves precision assembly rather than material removal or heavy fastening. In applications such as electronics assembly, small appliance manufacturing, furniture hardware installation, and enclosure assembly, the primary goal is not to drive a fastener as quickly as possible, but to achieve consistent results without damaging components. Drills are designed to deliver higher torque and speed, which can easily exceed what delicate fasteners or materials can tolerate.

An electric screwdriver offers finer control over rotational speed and torque, allowing users to seat screws accurately without stripping threads or cracking housings. This makes it suitable for assemblies where tolerances are tight and mistakes are costly. In these scenarios, the screwdriver is chosen not because it is weaker, but because it is more predictable and easier to manage.

Long-duration repetitive fastening and operator fatigue

Another clear situation where users prefer electric screwdrivers is during long periods of repetitive screwdriving. On assembly lines, repair benches, or installation jobs that require hundreds of similar fastening operations, ergonomics and fatigue management become critical factors. Drills are often heavier and generate more reaction force, which can strain wrists and forearms during extended use.

Electric screwdrivers are typically lighter and better balanced, especially models designed specifically for assembly work. Their reduced torque output also lowers the physical feedback transmitted to the user when the screw seats. Over time, this difference becomes meaningful, influencing productivity and comfort. Users who perform repetitive tasks often choose electric screwdrivers because they allow sustained operation with less physical stress.

Applications with high torque control requirements

Torque control is one of the most decisive reasons users select an electric screwdriver instead of a drill. Many fastening applications require screws to be tightened within a specific torque range to ensure proper function. Too little torque can lead to loosening, while too much can damage threads, deform parts, or compromise safety.

Electric screwdrivers often feature mechanical clutches, electronic torque settings, or automatic shut-off mechanisms designed for this purpose. While some drills offer clutch settings, their torque resolution is usually coarser and less consistent, particularly at the lower end of the range. In tasks such as plastic housing assembly, electrical terminal fastening, or precision metal components, users value the repeatability provided by electric screwdrivers.

| Application Type | Typical Torque Range | Preferred Tool | Reason |

| Electronics assembly | 0.2–1.5 Nm | Electric screwdriver | High control, low damage risk |

| Furniture assembly | 2–6 Nm | Electric screwdriver | Consistency and comfort |

| Wood framing | 15 Nm and above | Drill | Higher power demand |

Working in confined spaces and restricted environments

Space constraints strongly influence tool choice. In cabinets, electrical panels, appliance interiors, and vehicle interiors, maneuverability often matters more than power output. Drills, especially those with larger chucks and longer bodies, can be difficult to position in tight areas. Their size may force users into awkward angles that increase the risk of slipping or damaging surrounding components.

Electric screwdrivers are usually more compact and available in slim or angled designs. These characteristics make them easier to use in confined spaces where precise alignment is required. Users working in maintenance or installation roles frequently select electric screwdrivers because they allow access to fasteners that would be impractical to reach with a drill.

Light-duty tasks where drills are excessive

Many everyday fastening tasks simply do not require the power a drill provides. Hanging fixtures, assembling flat-pack furniture, installing switches, or adjusting fittings often involve small screws and moderate resistance. In these situations, a drill can feel excessive, both in terms of size and force.

Users often choose electric screwdrivers because they align better with the scale of the task. The reduced noise, smoother startup, and lower risk of overtightening contribute to a more controlled working experience. This preference is common among home users who want efficiency without sacrificing confidence or control.

Situations requiring consistent output rather than versatility

Drills are valued for their versatility. They can drill holes, drive fasteners, and handle a wide range of materials. Electric screwdrivers, by contrast, are chosen when consistency is more important than versatility. In environments where the same type of screw is driven repeatedly into similar materials, users benefit from a tool optimized for that single function.

This is particularly evident in light manufacturing and service operations. A dedicated electric screwdriver reduces setup time and minimizes variation between fastening cycles. Users who prioritize repeatable outcomes often prefer a specialized tool over a multifunction one.

Noise-sensitive and indoor working conditions

Noise levels can also influence tool selection. Drills tend to produce higher noise due to their motor characteristics and higher operating speeds. In offices, residential buildings, hospitals, or retail spaces, excessive noise can be disruptive.

Electric screwdrivers generally operate more quietly, especially at lower speeds. This makes them more suitable for indoor or occupied environments where minimizing disturbance is important. Users performing maintenance or installation work in such settings often choose electric screwdrivers to maintain a more controlled working atmosphere.

User skill level and confidence considerations

User experience and confidence play a role in tool choice. Less experienced users may find drills intimidating due to their power and potential for sudden movement. Electric screwdrivers feel more approachable, offering a sense of control that reduces the likelihood of mistakes.

This does not mean electric screwdrivers are limited to beginners. Skilled users also choose them deliberately when the task benefits from restraint rather than force. The decision reflects an understanding of application requirements rather than a limitation in capability.

Balancing efficiency with material protection

Ultimately, users choose electric screwdrivers instead of drills when efficiency must be balanced with material protection. Whether working with plastics, thin metals, or pre-threaded components, avoiding damage is often more important than completing the task as quickly as possible.

Electric screwdrivers occupy this middle ground by offering powered assistance while maintaining a level of control closer to manual tools. This balance explains why they remain relevant even as drills become more compact and powerful.

What Trade-Offs Are Manufacturers and Users Facing?

Balancing power output with physical size

One of the most persistent trade-offs faced by both manufacturers and users is the balance between power and size. Higher power output generally requires larger motors, stronger gear systems, and improved heat dissipation. These components inevitably increase the overall dimensions of the tool. For manufacturers, reducing size while maintaining acceptable performance demands more complex engineering and higher material costs.

From the user perspective, compact tools are easier to handle, store, and use in confined spaces. However, smaller tools may struggle with tasks that involve higher resistance or longer duty cycles. Users must decide whether they value portability over the ability to handle more demanding applications. This tension shapes product design decisions and influences how tools are positioned in the market.

Torque accuracy versus production and retail cost

Torque accuracy is a key performance attribute, especially in assembly and fastening applications. Achieving consistent and repeatable torque often requires precise sensors, electronic control systems, and calibration processes. For manufacturers, incorporating these features increases development complexity and production cost.

Users, on the other hand, may not always require high levels of torque precision. In many DIY or light installation tasks, approximate torque control is sufficient. The challenge lies in aligning product capabilities with user expectations. Tools designed for high torque accuracy are often priced beyond what casual users are willing to pay, while lower-cost options may fail to meet the needs of professional or semi-professional users.

| Torque Control Level | Typical Technology | Cost Impact | Common User Group |

| Basic | Mechanical clutch | Lower | Home DIY |

| Intermediate | Electronic speed control | Moderate | Installers, technicians |

| Advanced | Sensor-based shut-off | Higher | Assembly operations |

Multifunction tools versus dedicated solutions

The debate between multifunction tools and dedicated solutions continues to shape the electric screwdriver market. Multifunction tools appeal to users who want flexibility and reduced tool inventory. By combining drilling and fastening capabilities, manufacturers can offer products that address a wider range of tasks.

Dedicated electric screwdrivers, however, are optimized for specific applications. They often provide better balance, more consistent output, and simpler interfaces. For users who perform repetitive or specialized tasks, a dedicated tool can improve efficiency and comfort. Manufacturers must decide whether to prioritize versatility or specialization, knowing that each approach limits appeal to certain segments.

Battery capacity in conflict with tool weight

Battery selection presents another critical trade-off. Higher capacity batteries extend runtime and reduce the frequency of charging, which is attractive to users working on longer tasks. However, larger batteries add weight and bulk, affecting balance and increasing fatigue during prolonged use.

Manufacturers attempt to address this conflict by offering multiple battery options or designing tools compatible with shared battery platforms. Users then choose between lighter configurations with shorter runtime or heavier setups with extended operation. This choice often depends on how and where the tool is used, rather than on a single universally preferred specification.

Durability versus cost-sensitive materials

Durability is often associated with reinforced housings, metal gear components, and protective features. These elements increase tool lifespan but also raise material and manufacturing costs. In price-sensitive markets, manufacturers may opt for lighter materials or simplified construction to meet target price points.

Users face the resulting compromise. Lower-cost tools may perform adequately for occasional use but may not withstand repeated or demanding applications. Professional users are more likely to invest in durability, while casual users may accept shorter service life in exchange for lower upfront cost.

Thermal management and performance consistency

As tools become more compact and powerful, managing heat becomes increasingly challenging. Effective thermal management requires space, airflow, or additional components, all of which can affect size and cost. Manufacturers must decide how much sustained performance to support before thermal limits reduce output.

Users experience this trade-off as performance consistency. A tool that delivers high initial power but reduces output during extended use may be suitable for short tasks but frustrating in longer sessions. Understanding these limits influences user satisfaction and purchasing decisions.

User simplicity versus feature complexity

Adding features such as digital displays, multiple modes, and adjustable settings can enhance control and adaptability. However, increased complexity can also make tools harder to use, particularly for less experienced users. Manufacturers must balance innovation with usability.

Some users prefer straightforward tools with minimal controls, valuing reliability over customization. Others appreciate the ability to fine-tune performance. This divergence in preferences forces manufacturers to make careful decisions about interface design and feature sets.

Market positioning shaped by unavoidable compromises

Every design decision involves compromise. Whether balancing power and size, accuracy and cost, or runtime and weight, manufacturers navigate constraints imposed by physics, economics, and user expectations. Users, in turn, select tools based on which trade-offs align with their specific needs.

The electric screwdriver category illustrates how these trade-offs do not represent shortcomings, but rather reflect deliberate choices. Understanding these compromises helps explain why no single tool configuration satisfies all users, and why diversity within the category continues to expand.

What Should Buyers and Distributors Pay Attention to Right Now?

The gap between rated torque and real-world performance

One of the first issues buyers and distributors should examine is the difference between rated torque values and actual performance in use. Many electric screwdrivers are marketed with a single torque figure that represents a peak or theoretical maximum under ideal conditions. In real applications, however, torque output is influenced by factors such as battery charge level, motor efficiency, control electronics, and even ambient temperature.

For buyers, especially those sourcing tools for assembly, maintenance, or resale into professional channels, relying solely on catalog specifications can be misleading. A tool that claims a certain torque rating may not deliver that level consistently during normal operation. Distributors need to understand how torque is measured, whether it refers to stall torque, working torque, or electronically limited torque, and how that translates into customer expectations. Clear communication around these differences can reduce disputes and improve long-term trust.

Stability during continuous or repetitive operation

Another critical area of attention is performance stability during continuous use. Many electric screwdrivers perform adequately in short demonstrations or occasional tasks but reveal limitations when used repeatedly over extended periods. Heat buildup, battery voltage drop, and motor control behavior can all affect output consistency.

For buyers operating in light manufacturing, repair centers, or service environments, stability often matters more than peak specifications. A tool that maintains predictable speed and torque over dozens or hundreds of fastening cycles is generally more valuable than one that delivers higher output briefly but degrades quickly. Distributors evaluating products for these markets should look beyond initial impressions and consider endurance testing, duty cycle ratings, and user feedback related to prolonged operation.

Consistency challenges in bulk procurement

When purchasing electric screwdrivers in volume, consistency between units becomes a major concern. Even small variations in torque output, trigger response, or clutch behavior can create problems in assembly or quality-sensitive applications. These differences may not be noticeable to individual consumers but can have cumulative effects in batch operations.

Distributors sourcing from multiple production batches or factories need to pay close attention to quality control processes. Buyers should ask how manufacturers manage calibration, component tolerances, and final inspection. Inconsistent performance across a batch can increase return rates, complicate after-sales support, and damage brand reputation in downstream markets.

| Evaluation Aspect | Single-Unit Purchase | Bulk Purchase | Potential Risk |

| Torque consistency | Often overlooked | Critical | Assembly variation |

| Component tolerance | Less visible | Highly relevant | Quality deviation |

| Calibration control | Rarely checked | Necessary | Process instability |

Understanding how tools behave under load

Buyers and distributors should also pay attention to how electric screwdrivers behave under load rather than in no-load conditions. Speed drop, vibration, and control response when driving screws into different materials can vary significantly between models. These characteristics are rarely fully described in product literature.

In practical terms, a tool that feels smooth and controllable under resistance often delivers a better user experience than one that simply reaches a higher unloaded speed. For distributors, hands-on evaluation or feedback from pilot customers can provide insights that specifications alone cannot capture. Understanding these behaviors helps align products with appropriate applications.

After-sales support as part of the product value

After-sales service has become a defining factor in tool selection, particularly for distributors serving professional or semi-professional markets. Electric screwdrivers, despite their relatively simple appearance, rely on batteries, electronics, and mechanical components that may require maintenance or replacement over time.

Buyers should consider whether spare parts such as batteries, chargers, clutches, and switches are readily available. Distributors need to evaluate how responsive manufacturers are to warranty claims, technical questions, and documentation requests. A product with limited after-sales support may appear competitive at first but can create long-term challenges in customer retention and brand credibility.

The maturity of the accessory and spare parts ecosystem

Closely related to after-sales support is the maturity of the accessory ecosystem. Electric screwdrivers depend on consumables and accessories such as bits, extensions, battery packs, and charging solutions. Compatibility and availability of these items influence overall ownership cost.

For buyers managing fleets of tools, standardized accessories simplify inventory and training. Distributors should assess whether a product line supports common bit standards, whether batteries are shared across models, and how long accessories remain available after a model update. A fragmented ecosystem can limit scalability and increase operational complexity.

Transparency in specification and communication

Clear and transparent communication from manufacturers is increasingly important. Buyers and distributors benefit when specifications are explained in practical terms rather than marketing language. Details such as duty cycle assumptions, torque tolerance ranges, and battery performance curves help set realistic expectations.

In markets where electric screwdrivers are positioned across consumer and professional segments, ambiguity can lead to mismatched use cases. Distributors play a key role in translating technical information into application guidance. Doing so reduces misuse and enhances customer satisfaction.

Alignment between target market and actual design intent

Finally, buyers and distributors should evaluate whether a product’s design intent aligns with its target market. Some electric screwdrivers are adapted from consumer designs and marketed into light professional channels without sufficient reinforcement or testing. Others originate from industrial platforms but are simplified for broader appeal.

Understanding where a product sits on this spectrum helps buyers make informed decisions and helps distributors position it correctly. Misalignment can result in unmet expectations, higher return rates, and increased support demands. Paying attention to these signals allows stakeholders to navigate the current market more effectively.

References / Sources

Grand View Research — "Electric Power Tools Market Size, Share and Trends"

MarketsandMarkets — "Cordless Power Tools Market by Motor Type and Application"

Mordor Intelligence — "Electric Screwdriver Market Analysis and Industry Forecast"

Statista — "Global Power Tool Market: Consumer and Professional Segmentation"

McKinsey & Company — "The Future of DIY, Repair, and Home Improvement"

European Commission — "Right to Repair and Sustainable Product Policy Overview"

IEEE Spectrum — "Advances in Brushless Motor Control for Handheld Tools"

Assembly Magazine — "Torque Control and Fastening Accuracy in Modern Assembly Tools"

Research and Markets — "Lithium-Ion Battery Applications in Power Tools"

Harvard Business Review — "Product Positioning Challenges in Mature Tool Categories"

-

Feedback

English

English русский

русский Español

Español