Smooth start Voltage 20V (DC) Battery capacity 2.0Ah Motor type Brush motor Oscillations 8,000 - 19,000 OPM Oscillations angle 3.2 degree Charger 21V 0.5...

See Details-

Electric Woodworking Saw

-

Multifunctional oscillating Saw

-

Power Drill

-

Rotary Hammer Drill

-

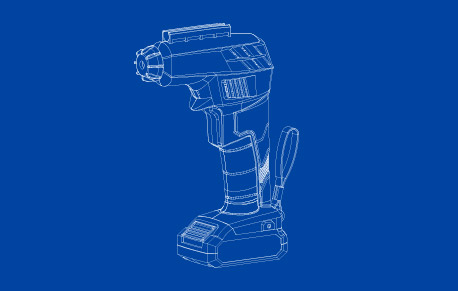

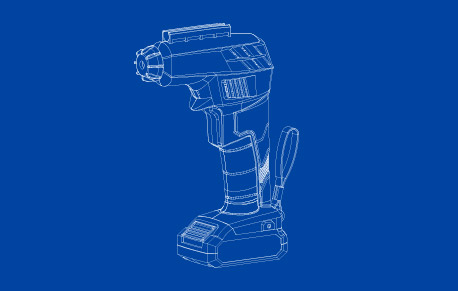

Impact Wrench

-

Electric Screwdriver

-

Angle Grinder

-

Handheld Pressure Washer

-

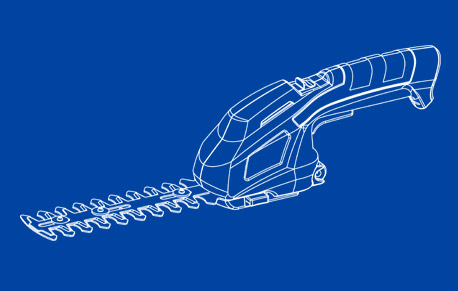

Handheld Lawn Mower

-

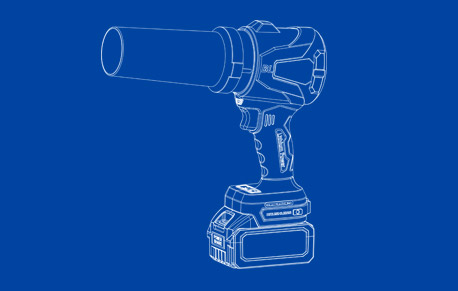

Lithium Turbo Jet Blower

-

Electric Pruning Shears

-

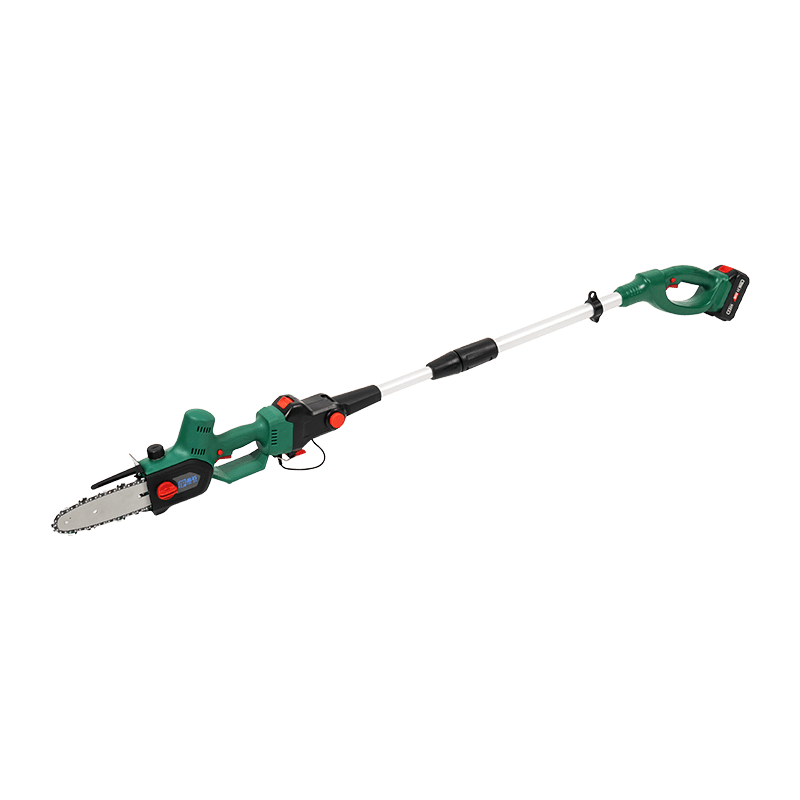

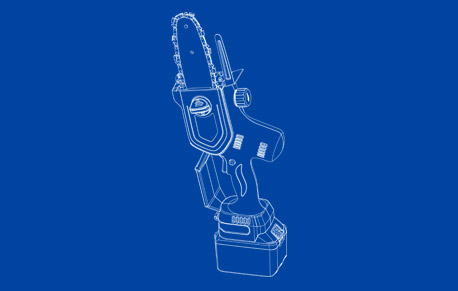

Lithium ChainSaw

-

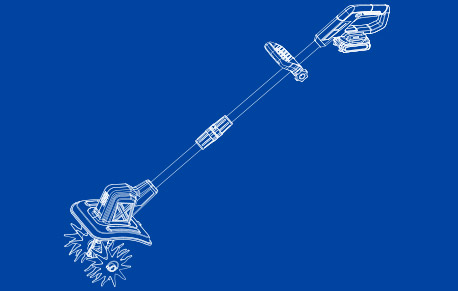

Handheld Tiller Cultivator

-

Plant Watering Devices

-

Air Pump

Pneumatic vs. Cordless: Which impact wrench actually delivers the nut-busting torque you need

Impact Wrench: Definition and Core Working Principle

The Impact Wrench, often referred to in industrial circles as an air gun, air wrench, or electric impact, is a professional-grade power tool specifically engineered to provide extremely high torque output with minimal effort from the user. Unlike a standard drill or a basic power screwdriver, the core mission of an Impact Wrench is not to rotate at high speeds to cut through material or drive small screws into wood. Instead, its purpose is to overcome the intense static friction and rotational resistance of heavy-duty fasteners—such as rusted lug nuts, industrial bolts, or large-diameter machinery screws—through high-frequency, instantaneous rotational impacts.

In the world of mechanical engineering and automotive repair, the Impact Wrench is considered the undisputed king of efficiency. It bridges the gap between manual labor and heavy industrial machinery. Where a human operator might struggle with a long breaker bar, risking physical injury or the breakage of the tool, the Impact Wrench utilizes internal physics to deliver a series of "hammer blows" that can loosen even the most stubborn, seized fasteners in a matter of seconds.

What is an Impact Wrench?

By technical definition, an Impact Wrench is a rotary impact tool that stores energy in a rotating mass and then delivers it suddenly to an output shaft. Its design intent is to allow the operator to output thousands of Newton-meters (N·m) of torque. The uniqueness of this tool lies entirely in the word "impact." Traditional drills rely on the continuous torque of a motor to force a bolt to turn; if the bolt is stuck, the motor stalls or the tool twists in the user's hand. In contrast, the Impact Wrench does not rely on steady force. It converts the rotational energy generated by its power source into discrete, high-velocity kinetic energy bursts, delivered directionally to the anvil.

This mechanism allows for massive torque without the corresponding reactionary force being transferred to the user's wrist. This is why a mechanic can hold an Impact Wrench that is outputting 1,000 N·m of torque with just one or two hands, whereas a standard drill outputting only 100 N·m would be nearly impossible to hold steady if the bit were to bind.

Internal Structure: The Source of Precision Power

To understand the sheer capability of an Impact Wrench, one must deconstruct its internal architecture. The tool is a marvel of mechanical synchronization, consisting of several critical components that work in a repeating cycle of energy accumulation and release.

Power Source (Motor): This is the primary mover of the tool. In pneumatic models, a vane-type air motor uses compressed air to spin at high velocities. In modern electric models, high-torque brushless DC motors have become the standard. The motor's sole job is to provide the initial rotational force to spin the internal hammer assembly.

Impact Mechanism (The Hammer and Anvil): This is the functional heart of the Impact Wrench. The Hammer is a heavy, precision-machined rotating mass. It is not fixed to the output shaft; instead, it is connected via a spring-loaded mechanism. The Anvil is the output shaft that holds the socket. The hammer spins freely to build up speed and then "strikes" the anvil, transferring all its momentum instantly.

Spring and Ramp System: This is the timing regulator of the tool. As the motor spins the hammer, a series of steel balls move along V-shaped ramps. When the resistance on the anvil becomes too great (i.e., the bolt won't turn), the balls climb the ramps, compressing a heavy-duty spring and pulling the hammer back. This allows the hammer to disengage, spin another 180 or 360 degrees to gain speed, and strike the anvil again.

Housing and Ergonomics: Because of the violent nature of the internal strikes, the housing of an Impact Wrench must be incredibly robust. Professional models use magnesium alloy or high-density reinforced composites. The handle is often decoupled or rubberized to dampen the high-frequency vibrations that can cause nerve damage over long-term use.

Application of Physics: Kinetic Energy Accumulation and Instantaneous Release

The working cycle of an Impact Wrench is a masterclass in the application of the impulse-momentum theorem. The cycle can be broken down into three distinct phases that occur hundreds of times per minute.

Acceleration Phase: The motor spins the Hammer. Because the fastener is currently stuck, the anvil is stationary. The hammer is allowed to spin freely, accelerating to its maximum RPM. During this time, it is accumulating rotational kinetic energy. The amount of energy stored is proportional to the mass of the hammer and the square of its rotational velocity.

Disengagement Phase: As the hammer continues to rotate against the resistance of the anvil, the internal cam-actuated spring compresses. The hammer "lifts" away from the anvil's lugs. This momentarily breaks the mechanical connection, preventing the motor from stalling and allowing the hammer to continue its high-speed rotation.

The Strike (Impact): Once the hammer has bypassed the anvil's lugs, the spring forces it forward again. The hammer's lugs then collide violently with the anvil's lugs. In this millisecond of contact, all the accumulated kinetic energy is transferred. This creates a massive torque spike that far exceeds the motor's actual power rating. It is this "shock" that breaks the chemical bonds of rust or the friction of a highly torqued thread.

Science Fact: Why does it make a "da-da-da" sound? The signature rhythmic clacking of an Impact Wrench is the literal sound of metal-on-metal collision. Each "clack" is one strike of the hammer against the anvil. If you hear 3,000 impacts per minute (IPM), it means the tool is delivering 3,000 individual torque bursts every sixty seconds. This relentless hammering is what makes the tool so effective against seized fasteners.

Differences Between Impact Wrenches and Drills/Drivers

Beginners often mistake the Impact Wrench for its smaller cousins. However, using the wrong tool for the job can lead to broken fasteners or ruined tools. The Impact Wrench is the "heavy artillery" of the power tool world.

| Feature | Standard Drill Driver | Impact Driver | Impact Wrench |

|---|---|---|---|

| Main Function | Drilling holes and driving small screws into wood or metal. | Driving long deck screws and self-tapping metal screws. | Loosening and tightening heavy-duty bolts and nuts. |

| Output Interface | Adjustable 3-jaw Chuck for round or hex bits. | 1/4" Hex Quick-change collet. | Fixed Square Drive (1/2", 3/4", 1"). |

| Torque Type | Continuous, steady rotational force. | Small, high-frequency radial impacts. | Massive, heavy-duty radial impacts. |

| Torque Level | 30 - 100 N·m | 150 - 250 N·m | 400 - 3,500+ N·m |

| Typical Fasteners | Drill bits, cabinet screws. | Wood screws, lag bolts. | Lug nuts, suspension bolts, anchor bolts. |

Power Source Classification: Choosing the Right Impact Wrench

The performance, weight, and utility of an Impact Wrench are primarily dictated by its power source. In the modern industrial landscape, choosing the right drive system is a balance between the required torque, the environment of the workspace, and the mobility needs of the technician.

Pneumatic Impact Wrench

Pneumatic Impact Wrenches have been the backbone of the automotive and manufacturing industries for nearly a century. They rely on a constant supply of compressed air to function. These tools are found in almost every professional garage and assembly line globally.

High Power-to-Weight Ratio: Because the tool does not need to house a heavy electric motor or a bulky battery pack, the pneumatic Impact Wrench is incredibly light relative to its power output. A 1/2" drive air impact can weigh as little as 2 kg while outputting over 1,300 N·m of torque. This is critical for mechanics who must hold the tool overhead for hours at a time.

Extreme Durability and Heat Resistance: Air tools are remarkably simple. They consist of a few moving parts and a vane motor. As the compressed air expands through the tool, it actually cools the internal components. This allows a pneumatic Impact Wrench to be used in continuous high-load cycles without the risk of thermal shutdown or electrical burnout.

Dependency on Infrastructure: The primary downside is the requirement for a robust air compressor system. A professional Impact Wrench requires high CFM (Cubic Feet per Minute) to reach its full potential. Using a small "pancake" compressor with a heavy-duty air gun will result in a tool that lacks the necessary "punch" to remove stubborn bolts.

Electric Impact Wrench (Corded and Cordless)

In the last decade, the electric Impact Wrench has undergone a revolution. Battery technology has advanced to the point where cordless models can now match or even exceed the power of traditional pneumatic tools.

Cordless Lithium-Ion Models: These have become the most popular choice for mobile mechanics, roadside assistance crews, and DIY enthusiasts. The primary advantage of a cordless Impact Wrench is its total lack of tethers. There are no hoses to trip over and no cords to limit your range. Modern "High Torque" cordless models utilize 18V or 20V platforms to deliver staggering amounts of power—sometimes exceeding 2,000 N·m of "nut-busting" torque. However, they are heavier due to the battery pack, and their performance can degrade as the battery charge drops.

Corded AC Models: While less common today, corded Impact Wrenches still serve a niche. They are ideal for users who do not have an air compressor and do not want to invest in a proprietary battery platform. They offer consistent, endless power but are limited by the proximity to an electrical outlet and the presence of a cord that can get caught in machinery.

Hydraulic Impact Wrench

Hydraulic Impact Wrenches are specialized tools used in the most extreme environments. They are powered by pressurized hydraulic fluid, typically supplied by a dedicated hydraulic power unit or the auxiliary power system of a tractor or service truck.

Extreme Duty and Underwater Use: Hydraulic systems are closed-loop, meaning they are completely sealed. This makes the hydraulic Impact Wrench the only viable option for underwater construction, such as bridge piling repair or oil rig maintenance. They provide the highest torque-to-size ratio of any tool and are virtually immune to environmental contaminants like mud, salt water, or dust.

Industrial Torque Requirements: These tools are often used in the mining and utility industries. When a bolt is 2 or 3 inches in diameter and requires 5,000+ N·m of torque, a hydraulic Impact Wrench is the only tool capable of the job.

Key Specifications: Understanding the Data Sheet

When selecting an Impact Wrench, the specification sheet can be overwhelming. Understanding these metrics is the only way to ensure the tool you purchase is capable of the tasks you intend to perform.

1. The Difference Between Fastening and Nut-Busting Torque

This is the most misunderstood specification in the industry. Manufacturers often highlight the "Nut-Busting Torque" in large font on the packaging. This refers to the tool's maximum ability to loosen a bolt that has already been tightened and perhaps seized by rust. It is an instantaneous peak measurement. "Fastening Torque," on the other hand, is the amount of force the tool can reliably apply when tightening a bolt from scratch. Usually, the loosening torque is 30% to 50% higher than the fastening torque. If you are working on heavy-duty truck suspension, you must prioritize the Impact Wrench with high nut-busting torque.

2. Impacts Per Minute (IPM) vs. Rotational Speed (RPM)

RPM (Revolutions Per Minute) tells you how fast the anvil spins when there is no load. Higher RPM means you can spin a long bolt out of a deep hole much faster. IPM (Impacts Per Minute) is much more important for actual power. It measures how many times the hammer hits the anvil. A high IPM allows the tool to maintain its torque delivery even when the bolt is moving slowly. For a professional Impact Wrench, a balance of high RPM (to save time) and high IPM (to break through rust) is ideal.

3. Drive Size: Matching the Tool to the Fastener

The "Drive Size" refers to the square anvil that the socket attaches to. This is a critical safety and performance choice.

1/4" and 3/8" Drive: These are for small-to-medium automotive work. They are perfect for engine bay work where space is tight and bolts are small (M6 to M12). They usually output between 100 and 400 N·m.

1/2" Drive: The "industry standard." This is the most versatile Impact Wrench size. It is used for wheel lug nuts, suspension components, and general machinery. It offers the best balance of power (up to 1,600 N·m) and maneuverability.

3/4" and 1" Drive: These are heavy-duty industrial tools. They are used for commercial trucks, semi-trailers, and large-scale construction. A 1" drive Impact Wrench is a "two-handed" tool that can output 3,000+ N·m of torque, enough to snap a standard passenger car's axle with a single trigger pull.

Essential Accessories: Impact Sockets and Maintenance

An Impact Wrench is only as good as the accessories used with it. Using the wrong accessories is the leading cause of tool failure and workplace injury.

The Critical Need for Impact-Rated Sockets

You must never use standard "chrome" sockets with an Impact Wrench. Standard sockets are made of Chrome Vanadium (Cr-V), which is very hard but brittle. Under the high-frequency hammering of an Impact Wrench, Cr-V sockets will develop microscopic cracks and eventually shatter like glass, sending metal shards flying at high speeds. Impact Sockets are made of Chrome Molybdenum (Cr-Mo). This steel is slightly softer and more ductile, allowing the socket to "absorb" the impact energy by deforming slightly rather than shattering. They are easily identified by their thick walls and black phosphate finish.

Maintenance for Longevity

To keep an Impact Wrench performing at its peak, regular maintenance is mandatory. For pneumatic models, this means adding 2-3 drops of specialized air tool oil into the air inlet every single day before use. This oil lubricates the vane motor and prevents internal corrosion from the moisture in the compressed air. For cordless models, maintenance focuses on the battery and the cooling vents. Dust and metal shavings can enter the motor housing and cause electrical shorts; therefore, blowing out the tool with compressed air once a week is a professional best practice.

Torque Sticks and Precision

Because an Impact Wrench is so powerful, it is very easy to over-tighten bolts. In the automotive world, over-tightening wheel nuts can warp brake rotors or stretch the wheel studs until they fail. Torque Sticks are color-coded extension bars designed to flex at a specific torque level. When the Impact Wrench reaches the stick's limit (e.g., 110 N·m), the stick begins to absorb the impacts, preventing further torque from reaching the nut. This is a vital tool for any tire service center.

Advanced Impact Mechanisms: Evolution of the Strike

As industrial needs have evolved, so too have the mechanical configurations inside the Impact Wrench. Different "clutch" designs offer varying levels of smoothness, speed, and raw power.

Twin Hammer Design: The Twin Hammer is the most popular professional mechanism today. It features two hammers that strike the anvil simultaneously from both sides. This creates a balanced blow with high instantaneous torque and incredible durability. It is the gold standard for 1/2-inch drive tools used in high-volume tire shops.

Rocking Dog Design: This is an older, simpler mechanism often found in larger, 3/4-inch and 1-inch drive pneumatic tools. It uses a single hammer that "rocks" onto the anvil. While it provides a very heavy blow, it is typically slower and produces more vibration than Twin Hammer designs.

Pin Clutch Design: This mechanism uses metal pins to engage the anvil. It is known for delivering very smooth, consistent torque. It is often preferred in assembly environments where a high degree of control is needed to prevent stripping threads on new components.

Single Hammer Design: Common in budget or compact tools, the single hammer strikes once per revolution. It is simple and lightweight but lacks the rapid-fire efficiency and balanced feel of more advanced multi-hammer systems.

Operation, Safety, and Troubleshooting

Operating an Impact Wrench requires respect for the power it contains. A single second of inattention can result in a snapped bolt that requires hours of drilling to remove, or worse, a crushed finger.

Safety First: Always wear impact-rated eye protection. The black phosphate coating on impact sockets can flake off, and rust from the bolt can fly into your eyes at high velocity. Hearing protection is also non-negotiable; air-powered Impact Wrenches often produce noise levels exceeding 105 decibels, which can cause permanent hearing loss in a very short time.

Correct Grip and Stance: To manage the vibration and weight, use a two-handed grip whenever possible. Stand with your feet shoulder-width apart to provide a stable base. This is especially important when using a high-torque Impact Wrench on a vertical surface, as the tool's weight can shift suddenly if a bolt breaks or spins free.

Preventing Cross-Threading: Never start a bolt with the Impact Wrench. Always hand-thread the fastener for at least three full turns until it is secure. Only then should you use the power tool to drive it home. The raw power of an Impact Wrench can strip threads instantly if the bolt is misaligned, leading to expensive repairs.

Troubleshooting Power Loss: If your Impact Wrench is losing power, start with the basics. For air tools, check the hose diameter. A 1/2" impact gun should be used with a 3/8" ID hose; using a thin 1/4" hose will starve the tool of air volume. For cordless tools, check the battery temperature. High-load work generates heat, and the battery's internal computer will throttle the power to prevent a fire. If the tool "clacks" but the bolt doesn't move, you may need a larger drive size or a penetrating lubricant to break the rust bond.

FAQ

Q: Can I use an Impact Wrench to tighten my wheel nuts?

A: Yes, but with extreme caution. You should use the lowest power setting to "snug" the nuts and then always use a manual torque wrench to finish the job to the manufacturer's exact specification. Never assume the Impact Wrench has hit the right number.

Q: What is the difference between a brushless and a brushed Impact Wrench?

A: A brushless Impact Wrench uses electronic controllers instead of physical carbon brushes to move the motor. This makes the tool more efficient, cooler-running, and much more durable since there are no brushes to wear out or replace.

Q: Why does my air Impact Wrench feel weak even though my compressor is set to 90 PSI?

A: Most likely, it is an air volume issue (CFM) rather than pressure (PSI). If your air hose is too long, too thin, or has restrictive "quick-connect" fittings, the tool cannot get enough air volume to move the heavy internal hammer at full speed.

Q: How often should I grease the hammer mechanism?

A: For heavy professional use, the internal hammer case should be cleaned and repacked with high-temperature lithium grease every 6 to 12 months. Most air Impact Wrenches have a small grease fitting on the side for this purpose.

Q: Will an Impact Wrench break small bolts?

A: Yes, very easily. Because of the high torque spikes, an Impact Wrench can snap a small M6 or M8 bolt before you even realize it is tight. For small fasteners, it is usually better to use an impact driver or a manual socket wrench.

Q: Can I use universal joints with an Impact Wrench?

A: Only if they are specifically impact-rated (usually black and beefier). Standard chrome universal joints will snap almost instantly under the stress of an Impact Wrench.

Q: Is it okay to use an Impact Wrench in the rain?

A: Pneumatic Impact Wrenches are generally safe in wet conditions, though they must be dried and oiled immediately afterward to prevent rust. Cordless or corded electric Impact Wrenches should never be used in wet or rainy conditions due to the risk of short-circuiting and electric shock.

Q: Why does my Impact Wrench only spin in one direction?

A: This is usually a failure of the reversing valve (in air tools) or the directional switch (in electric tools). It could also indicate that a piece of internal debris is jammed in the hammer cage. If the switch feels loose or won't engage, the tool requires professional repair.

-

Feedback

English

English русский

русский Español

Español