Smooth start Voltage 20V (DC) Battery capacity 2.0Ah Motor type Brush motor Oscillations 8,000 - 19,000 OPM Oscillations angle 3.2 degree Charger 21V 0.5...

See Details-

Electric Woodworking Saw

-

Multifunctional oscillating Saw

-

Power Drill

-

Rotary Hammer Drill

-

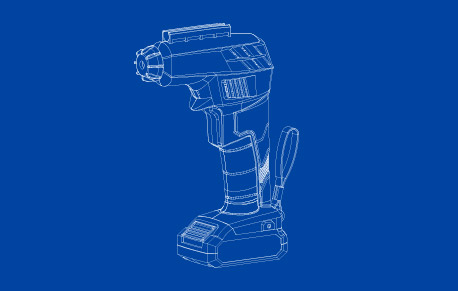

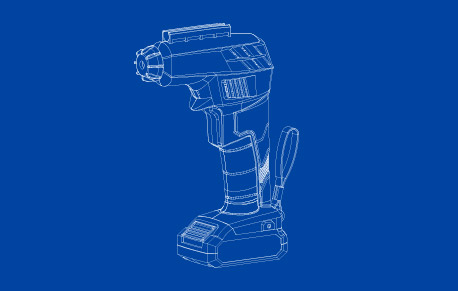

Impact Wrench

-

Electric Screwdriver

-

Angle Grinder

-

Handheld Pressure Washer

-

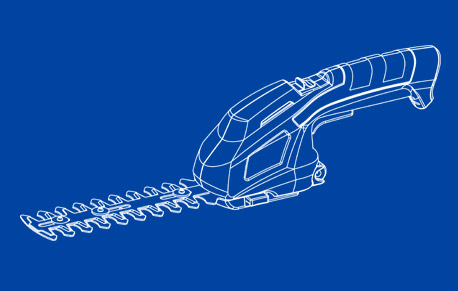

Handheld Lawn Mower

-

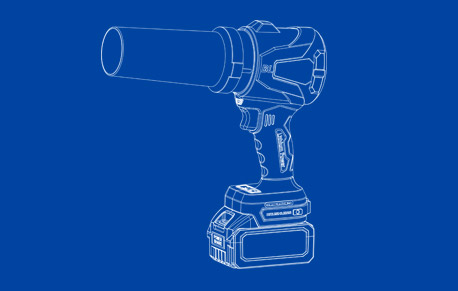

Lithium Turbo Jet Blower

-

Electric Pruning Shears

-

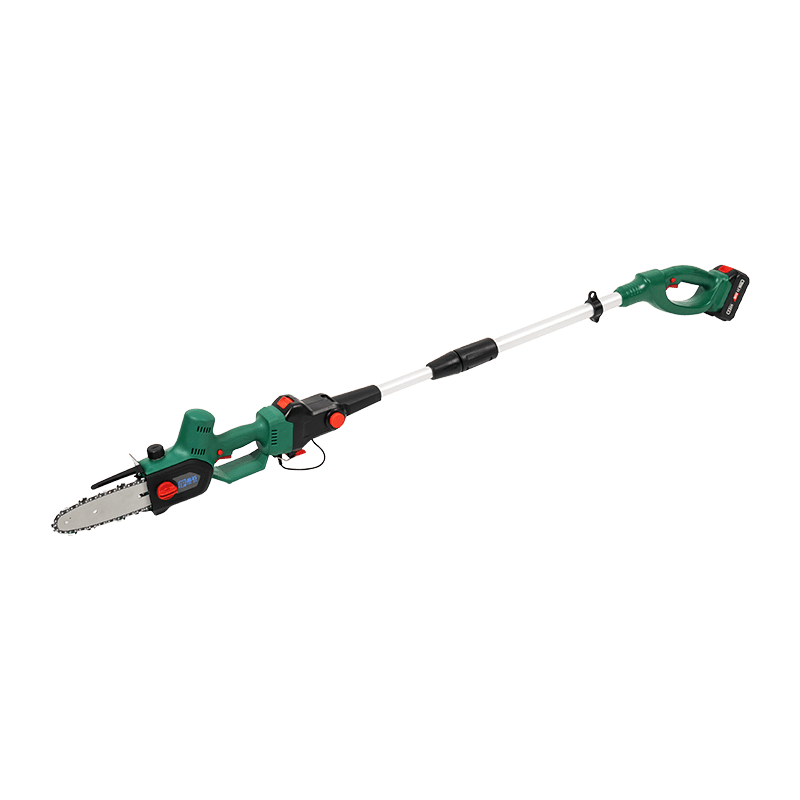

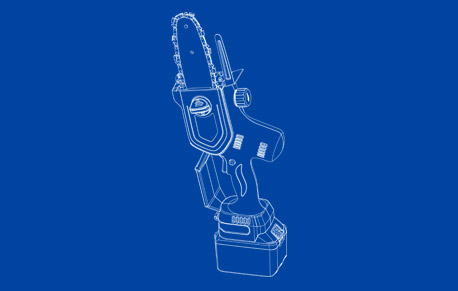

Lithium ChainSaw

-

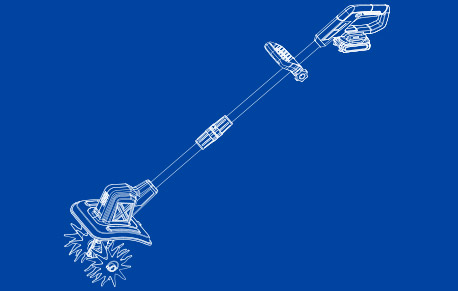

Handheld Tiller Cultivator

-

Plant Watering Devices

-

Air Pump

How to Choose the Perfect Impact Wrench? A 2026 Global Power Tool Market Analysis and Buyer’s Guide

In the rapidly evolving landscape of construction, automotive repair, and industrial assembly, one tool has consistently stood out as the backbone of efficiency: the Impact Wrench. As we move into 2026, the technological gap between professional-grade equipment and DIY tools is narrowing, thanks to revolutionary advancements in battery chemistry, motor design, and smart connectivity. This comprehensive report delves into the mechanics, selection criteria, and maintenance of the modern Impact Wrench, providing an essential roadmap for anyone looking to master their craft with precision and power.

Why Has the Impact Wrench Become the "Efficiency King" of Modern Repair and Construction?

The dominance of the Impact Wrench in today's modern workshops and heavy-duty industrial sites is by no means an accidental occurrence. It is the sophisticated result of over a century of engineering refinement and ergonomic evolution, culminating in a specialized power tool that solves the single most frustrating and time-consuming problem in mechanical engineering: the removal and fastening of stubborn, over-torqued, or heavily rusted fasteners that manual labor simply cannot budge without risk of injury or component damage.

What is the Core Working Principle of an Impact Wrench and Its Technical Evolution in 2026?

At its heart, an Impact Wrench is designed to deliver high torque output with minimal physical effort from the user, effectively decoupling the power needed for the task from the strength of the operator. Unlike a standard drill or driver that provides a constant, linear rotational force—which can often lead to wrist strain or tool kickback—the Impact Wrench utilizes a specialized internal "hammer and anvil" mechanism to generate massive bursts of kinetic energy.

High Torque Output Mechanism: When the tool encounters significant resistance, an internal spring-loaded hammer strikes an anvil connected directly to the output shaft. This creates a massive burst of rotational force (torque) combined with a high-frequency vibratory shock that helps break the static friction of a seized bolt. In 2026, these mechanisms have been further refined using aerospace-grade titanium and carbon-steel alloys, allowing for much higher BPM (Blows Per Minute) cycles without increasing the tool's physical footprint or weight. This is why a modern Impact Wrench can seamlessly break loose a structural bolt that would snap a traditional hand wrench or strip a standard power drill.

The Leap in Energy Efficiency: The most significant shift in the last decade has been the total transition from pneumatic (air-powered) systems to cordless high-density lithium-ion technology. The 2026 generation of Impact Wrench models features "Solid-State" battery cells that offer nearly 30% more runtime and faster discharge rates than those seen just two years ago. This has allowed the Impact Wrench to move from the stationary shop floor—tethered to a loud air compressor—to the remote job site or roadside emergency without compromising on "nut-busting" torque.

Intelligence Trends: We are now seeing the integration of AI-driven sensors and haptic feedback. Modern high-end Impact Wrench units include pressure-sensitive digital triggers and multi-stage automatic stop technologies. These systems can detect the exact micro-second a bolt has broken loose and instantly reduce the RPM to prevent the fastener from flying off dangerously, or conversely, detect when a bolt is seated and stop before over-tightening or "stretching" the metal occurs.

From Lightweight to Heavy Industrial: Which Specification of Impact Wrench Meets Your Specific Needs?

One size does not fit all in the professional world of 2026. The global market is now meticulously segmented by voltage, drive size, and motor type to cater to vastly different levels of operational intensity.

2026 Impact Wrench Voltage Platform Comparison

|

Specification |

Voltage |

Typical Torque Range |

Primary Application |

Weight Class |

|---|---|---|---|---|

|

Electric Assist |

4V |

5 - 15 Nm |

Electronics, Interior Trim |

Ultra-Light (< 0.5kg) |

|

Goldilocks |

16V |

150 - 450 Nm |

Light Auto, DIY, HVAC |

Mid-Light (1.2kg) |

|

Industrial Standard |

20V |

400 - 1,200+ Nm |

Heavy Repair, Construction |

Professional (1.8kg+) |

|

Extreme Duty |

40V/60V |

2,000+ Nm |

Mining, Heavy Infrastructure |

Heavy (3.5kg+) |

Can the 4V Electric Assist Ratchet Wrench Completely Replace Manual Ratchets?

The 4V Electric Assist Ratchet Wrench represents the high-precision "surgical" tier of the modern fastening world. While it intentionally lacks the raw, destructive power of a heavy-duty Impact Wrench, it has become an indispensable primary tool for delicate mechanical work where control is more valuable than brute force. It serves as a bridge between manual hand tools and high-torque power equipment, ensuring that small-scale assembly remains efficient without sacrificing the "feel" of the fastener.

Positioning:

This tool is the perfect technical hybrid. It provides the rapid rotation speed of a micro-electric motor with the tactile, high-torque feedback of a traditional manual ratchet. It is specifically designed for low-torque applications where the primary goal is to reduce the "swing time" of the user, making it a "speed tool" rather than a "power tool."

Key Advantages:

Extreme Portability and Spatial Geometry: The defining characteristic of this tool is its ultra-slim, ultra-low-profile head design. In the modern automotive and aerospace sectors, components are packed with increasing density, leaving virtually no room for traditional pistol-grip tools. The 4V ratchet's inline form factor allows it to reach deep into congested engine bays, intricate electrical control cabinets, and narrow aerospace bulkheads where a standard Impact Wrench or even a stubby driver simply cannot gain clearance. Its ability to act as a manual lever also means that even if the battery is depleted, the user can still apply manual "break-away" torque without switching tools.

Advanced Component Protection and Precision Engineering: Unlike its high-voltage cousins, the 4V platform features a low-voltage motor that is digitally governed by a precise electronic torque limiter. This is a critical safety feature designed to prevent the catastrophic stripping of fine threads or the snapping of small-gauge, low-tensile fasteners—errors that are remarkably common when using over-powered industrial tools on sensitive equipment. In 2026, these tools often feature "soft-start" triggers that allow for microscopic incremental adjustments, ensuring that every fastener is seated with surgical accuracy without risking damage to expensive consumer or automotive electronics.

Application Scenarios:

In the current industrial landscape, this tool is the gold standard for professional electronic device assembly, including server rack maintenance and robotics. In the automotive sector, it is the go-to choice for complex dashboard disassembly and interior cabin repairs where avoiding scratches and preserving delicate clips is paramount. Furthermore, it has seen massive adoption in the assembly of high-end, modular luxury furniture, where preserving the visual aesthetics and surface integrity of fine woods and soft metals is a non-negotiable requirement.

How Does the 16V Cordless Impact Wrench Balance Portability and Power?

For those who find the 4V platform too weak for mechanical tasks and the 20V platform too bulky for all-day use, the 16V Cordless Impact Wrench has emerged as the "Goldilocks" solution in 2026. This platform is specifically engineered for users who demand professional-level torque but cannot justify the weight penalty and muscular strain associated with high-voltage industrial gear.

The Mid-Range Champion and Market Logic:

This tier fills a critical strategic gap in the fastening tool market. It offers a surprising amount of torque—sufficient to handle most passenger vehicle lug nuts, suspension bolts, and critical engine bay components—while remaining light enough to be used overhead or in awkward, non-neutral positions for extended periods. This balance significantly reduces the risk of repetitive strain injuries and "muscular fatigue," which often occurs when a technician is forced to maneuver a heavy 20V unit in a cramped wheel well for hours on end.

Detailed Technical Highlights:

Revolutionary Compact Battery Engineering: Utilizing the very latest in cell-stacking technology and high-nickel cathodes, the 16V Cordless Impact Wrench maintains a compact, lightweight footprint that rivals the 12V tools of a decade ago. Despite its small size, the energy density allows it to deliver nearly double the effective work capacity and peak discharge current of previous mid-voltage generations.

Versatility and Environmental Adaptability: This tool is an all-rounder. It is equally at home in a professional interior trim shop, where precision is needed to avoid damaging upholstery, as it is in a residential home garage for routine light mechanical maintenance. Its motor is tuned to provide a linear power curve, making it just as effective at low-speed threading as it is at high-speed fastener removal.

Target Users and Ergonomic Focus:

This is the ideal tool for the dedicated DIY enthusiast and the semi-professional technician who values "swing-weight" and tool balance over raw, peak torque numbers. In 2026, user-centric design has made this platform a favorite for mobile mechanics and emergency roadside responders who need a reliable, high-output Impact Wrench that doesn't consume excessive space in a service vehicle.

Why Has the 20V Li-ion Impact Wrench Become the Standard for Professional Technicians Worldwide?

The 20V Li-ion Impact Wrench is the undisputed, heavy-duty workhorse of the modern industrial era. If you walk into any high-throughput professional dealership, a military aircraft hangar, or a large-scale infrastructure construction site, this is the specific tool you will see anchoring every technician's primary arsenal. Its dominance is not just based on raw power, but on the reliability and versatility that the 20V platform provides to the most demanding industrial sectors.

The Power of Global Standardization and Ecosystem Integration:

In 2026, the 20V platform has solidified its position as the universal industry standard for cordless power. Major manufacturers have invested billions in building entire professional "ecosystems" around this specific voltage. This means a technician can seamlessly swap high-capacity, smart-connected batteries between their primary Impact Wrench, heavy-duty hammer drills, high-torque reciprocating saws, and high-lumen job site lighting. This interoperability eliminates the need for multiple charging platforms, drastically reducing clutter and overhead costs for large-scale operations.

Industry-Leading Performance Characteristics:

Extended Industrial Endurance: When equipped with the latest 5.0Ah or 6.0Ah high-capacity lithium-ion battery packs, a 20V Li-ion Impact Wrench is capable of handling a full, grueling day of heavy-duty tire rotations on commercial trucks or structural bolting on steel frames on a single charge cycle. The discharge curves of these batteries are electronically managed to ensure that the tool delivers 100% of its rated torque until the very last drop of energy is consumed.

Rapid Multi-Stage Charge Technology: Modern smart-charging stations in 2026 can bring a depleted 20V battery to 80% capacity in under 30 minutes. This technology, combined with thermal management systems that prevent the battery from overheating during the charge cycle, ensures virtually zero downtime even during the most demanding triple-shift industrial projects.

Comprehensive Durability and Field Assessment:

These tools are engineered to thrive in environments that would destroy consumer-grade equipment. They are built to survive the standard "10-foot drop-test" on concrete, which is a common reality of a fast-paced job site. Their construction features specialized chemical-resistant rubberized over-molds that protect the casing from hydraulic fluids and oils, while fully sealed internal electronics and conformal-coated circuit boards provide a defensive barrier against the fine metallic shavings, abrasive dust, and high-humidity moisture typical of harsh, real-world industrial environments.

Performance Monster: Why the 20V Brushless Impact Wrench is the Top-Tier Choice Today?

When we talk about the pinnacle of power tool engineering in 2026, we are talking about the 20V Brushless Impact Wrench. This tool represents the ultimate combination of digital motor efficiency and raw, unbridled mechanical power.

How Does Brushless Motor Technology Redefine the Performance Ceiling of a 20V Impact Wrench?

The shift from brushed to brushless motors is the most significant upgrade a professional can make to their kit. This transition marks the end of the "analog" tool era and the rise of the software-defined powertrain, where performance is limited only by magnetic flux and battery discharge rates.

Superior Thermal Management and Electronic Efficiency: Traditional motors rely on physical carbon brushes that create constant friction, electrical sparks, and significant heat loss. The 20V Brushless Impact Wrench eliminates these mechanical failure points entirely, utilizing an intelligent digital controller to manage a high-frequency rotating magnetic field. This electronic commutation reduces heat buildup significantly, allowing the motor to run much cooler under sustained heavy load. As a result, the tool's duty cycle is dramatically extended, often lasting more than 50% longer than its brushed counterparts before requiring a thermal cool-down period.

Drastic Improvement in Power-to-Weight Ratio: Because the brushless motor is inherently more efficient and lacks the bulky housing required for brushes and commutators, manufacturers can produce a 20V Brushless Impact Wrench that is smaller, shorter, and lighter than ever before. This increased power density allows for a compact "stubby" unit to produce significantly more "breakaway torque" than full-sized tools of the previous generation. In 2026, it is not uncommon for a mid-size brushless unit to produce over 1,000 ft-lbs of nut-busting torque—a performance figure once reserved exclusively for massive, stationary pneumatic industrial tools.

Long-Term Investment Value and Operational ROI: While the initial purchase price of a 20V Brushless Impact Wrench is typically higher, the "Total Cost of Ownership" (TCO) is drastically lower over the life of the tool. With no carbon brushes to wear out, replace, or maintain, the mechanical downtime is virtually zero. Furthermore, the motor's increased efficiency translates to a battery runtime that is roughly 30% better per charge cycle. For a professional workshop, the productivity gains from faster fastening cycles and fewer battery swaps mean the tool's price premium is usually recovered within just a few months of active, daily service.

How to Extend the Service Life of Your Impact Wrench Through Scientific Maintenance?

Even the most advanced Impact Wrench will fail prematurely if neglected in a high-intensity professional environment. Scientific maintenance is not merely about cleaning; it is a systematic approach to technical preservation, ensuring that your 20V or 16V tool continues to deliver its factory-rated peak torque year after year without internal mechanical decay.

Which Daily Maintenance Details Effectively Prevent Power Decay?

Sophisticated Battery Health Management: Lithium batteries are the chemical lifeblood of the modern Impact Wrench. Exposure to extreme thermal gradients—such as direct summer sunlight on a dashboard or sub-zero overnight temperatures in a service vehicle—causes irreversible internal resistance buildup. Ideally, batteries should be stored in a climate-controlled environment and maintained between 30% and 80% charge during periods of inactivity. This "storage window" prevents the chemical electrolyte from stagnating or degrading, significantly extending the cycle life of the expensive high-capacity cells.

Drivetrain and Impact Mechanism Lubrication: The "hammer and anvil" mechanism inside an Impact Wrench generates immense internal friction and extreme localized heat during high-load fastening cycles. Over time, factory grease can break down or become contaminated with metallic micro-debris. Periodic inspection of the front gear housing and re-greasing with manufacturer-approved high-pressure molybdenum or synthetic lubricants is essential. Proper lubrication ensures that the kinetic energy from the hammer is transferred efficiently to the anvil rather than being wasted as heat or causing abrasive metal-on-metal wear.

Proactive Environmental Protection and Airflow Maintenance: Professional work sites are often filled with conductive metallic dust or abrasive masonry particles. After working in these conditions, it is critical to use low-pressure dry compressed air to blow out the motor vents and battery interface ports. Fine metallic dust buildup acts as a thermal insulator, trapping heat around the motor windings and potentially causing the sophisticated electronic control board (ESC) to short circuit or suffer a catastrophic thermal failure. Maintaining clear airflow is the simplest way to prevent the "silent killer" of modern brushless tools: heat-induced power decay.

Impact Wrench vs. Similar Fastening Tools: Who is the King of the Scenario?

In 2026, the global marketplace is increasingly crowded with specialized power tools that share similar aesthetics but serve fundamentally different engineering purposes.

Impact Wrench vs. Impact Driver - Key Technical Differences

|

Feature |

Impact Wrench |

Impact Driver |

|---|---|---|

|

Output Interface |

1/2", 3/8", or 3/4" Square Drive |

1/4" Hex Quick-Release Chuck |

|

Primary Target |

Heavy Bolts, Lug Nuts, Structural Hardware |

Screws, Self-Tappers, Small Fasteners |

|

Torque Level |

Ultra-High (up to 2,000+ Nm) |

Moderate (up to 250 Nm) |

|

Mechanism Focus |

Mass-Momentum Shock |

High-Speed Pulse |

|

Tool Accessory |

Impact-Rated Sockets |

Hex Shank Bits |

What Absolute Advantages Does an Impact Wrench Have Over an Impact Driver in Industrial Applications?

Many beginners and even some seasoned tradespeople frequently conflate the Impact Wrench with its smaller cousin, the Impact Driver, due to their superficial visual similarities and overlapping nomenclature. However, while they may look nearly identical from a distance in a crowded workshop, their internal engineering blueprints, mechanical tolerances, and fundamental operational capabilities are worlds apart. Failing to distinguish between these two can lead to catastrophic tool failure, damaged fasteners, or significant workplace safety risks.

Hardened Output Design and Drive Interface: The most visible difference is the drive system. The Impact Wrench utilizes a heavy-duty, solid Square Drive (standardized in 1/2", 3/8", or 3/4" sizes). This thick metal interface is designed to withstand the massive, jarring rotational torque loads required to overcome the static friction of large, structural bolts. In stark contrast, the Impact Driver uses a 1/4" Hex Chuck, which is engineered for high-speed rotation and the driving of long wood screws or self-tapping fasteners into lighter materials.

Massive Disparity in Power Levels and Component Durability: If you attempt to use a standard Impact Driver to remove a seized truck lug nut or a rusted suspension bolt, the outcome is predictable: you will likely snap the hex bit, strip the internal clutch, or burn out the motor's windings within seconds. The Impact Wrench is engineered specifically for "mass-momentum" impacts, utilizing much heavier internal strike blocks to move high-tensile fasteners that would simply destroy a lighter driver. It is the difference between a sledgehammer and a finishing hammer.

Rotational Inertia and User Ergonomic Protection: The heavy internal "strike block" of an Impact Wrench is strategically designed to absorb and redirect the majority of the rotational kickback within the tool's own reinforced housing. This means that while the tool is delivering a bone-shaking 800 or 1,000 ft-lbs of torque to the bolt, very little of that twisting force is transferred back to the user's wrist or arm. This internal dampening makes the Impact Wrench significantly safer and less fatiguing for high-torque tasks than a standard high-power drill, which can snap a user's wrist if the bit binds suddenly.

What Revolutionary Advances Does the 20V Brushless Series Have Over Traditional Pneumatic Wrenches?

For nearly a century, the air-powered (pneumatic) wrench was the only viable choice for high-torque professional work, serving as the undisputed king of the industrial automotive bay and heavy manufacturing plant. These legacy systems relied on a complex infrastructure of air compressors, drying units, and vast networks of reinforced hoses that dominated the acoustic and spatial environment of the shop floor. However, the technological landscape changed decisively in 2026 with the arrival of high-discharge brushless systems and ultra-compact "Solid-State" battery chemistry. This shift represents more than just a change in power source; it is a fundamental re-imagining of industrial powertrain efficiency, moving from the mechanical limitations of compressed air to the precision of software-governed electromagnetic force.

Breaking the Shackles of the Air Hose: The most immediate and profound advantage of a 20V Brushless Impact Wrench is absolute job site mobility. Comprehensive field tests in 2026 have demonstrated that technicians in large-scale shipyards, structural steel assembly sites, or multi-bay automotive centers improve their movement efficiency by over 30% when they are no longer tethered to heavy, tangling air hoses. The elimination of the hose also removes a major tripping hazard and allows for work in remote locations where bringing a loud, bulky air compressor is logistically impossible.

Digital Consistency vs. Pneumatic Fluctuation: Traditional pneumatic tools are entirely at the mercy of the shop's air pressure stability. If the compressor cycles down, if there is a leak in the line, or if another technician begins using a high-flow tool on the same manifold, the wrench instantly loses its "nut-busting" power. An electronic 20V Brushless Impact Wrench provides a perfectly consistent, digitally regulated power curve. Whether the battery is at 95% or 15%, the integrated software ensures the motor delivers the exact amount of torque requested by the trigger, regardless of external shop conditions.

Auditory Health and Environmental Sustainability: The deafening "exhaust" and high-pitched whine of a pneumatic tool are major contributors to permanent hearing loss and worker fatigue in professional environments. The 20V Brushless Impact Wrench operates at a significantly lower decibel level and completely eliminates the need for oil-misted air exhaust, which can contaminate the workspace and harm the technician's respiratory health. Switching to cordless systems creates a cleaner, quieter, and ultimately more professional workspace.

Why Does an Impact Wrench Still Need to Be Paired with a Manual Torque Wrench in Precision Assembly?

Despite the staggering raw power and sophisticated smart-sensing technology of a modern Impact Wrench, it remains a tool of "force" rather than "finality." In 2026, professional standards dictate that it is not a "one-and-done" solution for every critical stage of high-stakes industrial assembly. Understanding the specific boundary where power tool efficiency ends and manual precision begins is essential for maintaining engineering integrity.

The Vital Division of Labor: In professional engineering settings, the Impact Wrench is utilized exclusively for the "heavy lifting" phase of a project—speedily running a long, high-friction structural bolt down or breaking a decades-old frozen fastener loose. However, the final tightening to a safety-critical specification (such as the 85 ft-lbs required for a passenger vehicle wheel nut or the precise tolerances of a bridge support) must be finalized with a calibrated manual torque wrench. This manual step ensures total compliance with legal safety mandates and prevents the catastrophic failure of components that are over-stressed by the tool's inherent vibrational energy.

Complex Risk Mitigation and Material Integrity: Using a high-output Impact Wrench on fragile or exotic materials—such as cast aluminum cylinder heads, carbon fiber reinforced polymers, or soft plastic housings—carries an extreme risk of "torque over-shoot" or thread galling. The rapid-fire impacts of the hammer mechanism can microscopicially fatigue the metal before the user can even react to the trigger. By strategically using the Impact Wrench for the first 90% of the fastening cycle and finishing the remaining 10% manually, the technician ensures a perfect, scientifically verifiable balance of industrial speed and surgical precision.

The Critical Ecosystem: Sockets, Drive Sizes, and System Matching

In the professional high-torque environment of 2026, the Impact Wrench is only as effective as the socket system it is paired with. A mismatch between the tool’s output and the accessory's material properties can lead to substantial kinetic energy loss, irreversible equipment damage, or severe personal safety hazards. The interface between the tool and the fastener is where the physics of high-frequency impact meets the reality of material science.

Why Must You Use Specialized Impact Sockets Instead of Standard Chrome Sockets?

It is a common but dangerous mistake to use standard chrome-vanadium (Cr-V) hand tool sockets with a high-torque Impact Wrench. In 2026, the peak torque figures of brushless tools—frequently exceeding 1,500 Nm—have officially surpassed the structural limits of standard hand-tool metallurgy, making specialized impact-rated accessories a mandatory safety requirement.

Metallurgical Differences (Cr-Mo vs. Cr-V): High-quality impact sockets are forged from Chrome-Molybdenum (Cr-Mo) steel. Unlike the hard but brittle chrome sockets used for manual hand tools, Cr-Mo is a more ductile and "forgiving" alloy. This ductility allows the socket to slightly deform elastically and "absorb" the high-frequency vibrations and violent, instantaneous hammer strikes without shattering. In contrast, standard chrome sockets, when subjected to the high-BPM pulses of a 20V brushless wrench, act like glass; they cannot flex under the load and will eventually succumb to microscopic fatigue cracks that lead to explosive failure.

Surface Coating and Wall Thickness: Impact sockets feature a black phosphate or black oxide coating rather than a shiny, decorative chrome finish. This is a critical functional choice: chrome plating is prone to peeling and flaking off under the high-frequency stress of an impact tool, creating razor-sharp metallic debris. Furthermore, impact-rated sockets are engineered with significantly thicker walls to handle the extreme kinetic loads and provide a deeper engagement with the anvil. This extra mass ensures that the square drive interface doesn't "roll over" or strip under peak stress, ensuring 100% of the tool's torque is delivered to the fastener rather than being wasted through socket wall expansion.

The Evolution of "Non-Slip" Geometry: In 2026, premium impact sockets incorporate "Radius Corner" designs. This internal geometry shifts the contact pressure away from the sharp, fragile corners of the bolt head and onto the flat, stronger sides. This advancement, combined with the energy-absorbing properties of Cr-Mo steel, virtually eliminates the risk of rounding off expensive or critical fasteners, even when the Impact Wrench is operating at its maximum "nut-busting" setting.

Selecting the Right Drive Size (1/2", 3/8", 3/4") for the Task

The drive size—referring to the physical dimensions of the square output anvil—acts as the primary mechanical fuse and transmission link of the system. It dictates the maximum sustainable torque the entire assembly can handle before the physical metal reaches its plastic deformation or shear point. In 2026, understanding these thresholds is critical for both safety and tool longevity.

3/8" Drive (Compact Precision & Agility): This size is the premium choice for the 16V or mid-torque 20V "stubby" platforms. It is specifically engineered for modern automotive engine bays where spatial geometry is a major constraint. While compact, it is a "high-density" power link, now capable of handling more than 300 Nm of sustained force. It is the gold standard for intricate tasks involving suspension linkages, brake caliper bolts, and high-performance motorcycle maintenance where access is tight but hand tools are insufficient.

1/2" Drive (The Universal Professional Standard): Found on the vast majority of high-output professional 20V and 18V units, the 1/2" drive is the industry benchmark for versatility. It offers the optimal mathematical balance between physical anvil thickness and rotational inertia. This size is capable of reliably transmitting torque ranges from 400 Nm to 1,600 Nm without significant metal fatigue. It is the indispensable workhorse for heavy-duty tire services, agricultural equipment maintenance, and structural steel bolting in commercial construction.

3/4" and 1" Drive (Heavy Industrial Monsters): These massive drive interfaces are reserved exclusively for the "Extreme Duty" 40V/60V high-voltage platforms. They are designed for industrial applications where the bolts themselves are large enough to require torque figures exceeding 2,500 Nm—force levels that would instantly shear or "twist off" a standard 1/2" anvil. These drives are the backbone of the mining industry, heavy railway infrastructure, and naval shipyard maintenance, where the integrity of massive, large-diameter fasteners is a matter of critical infrastructure safety.

Navigating the 2026 Impact Wrench Landscape

The Impact Wrench has transitioned from a crude, loud industrial tool to a sophisticated piece of digital machinery. Whether you are looking for the extreme portability and finesse of a 4V Electric Assist Ratchet Wrench, the balanced performance of a 16V Cordless Impact Wrench, or the uncompromising, professional-grade power of a 20V Brushless Impact Wrench, the technology of 2026 offers a solution for every bolt and every builder. By understanding these power tiers and committing to a regimen of scientific maintenance, you can ensure that your Impact Wrench remains the most reliable and efficient partner in your professional toolbox for decades to come.

-

Feedback

English

English русский

русский Español

Español